This article was first published on the ZHAW Digital Futures Lab blog. The interview was conducted by Johanna Seiwald (ZHAW digital).

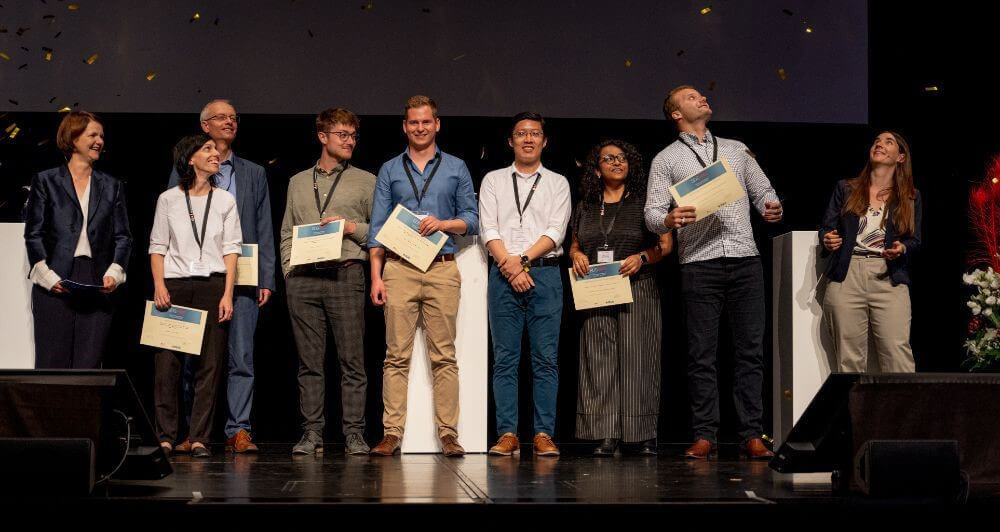

Congratulations Dr. Lilach Goren Huber for winning the Best Presentation Award and DIZH fellow Dr. Jürg Meierhofer for the Best Paper Award at the Swiss Conference on Data Science (SDS) this year! The SDS is the most important Swiss conference for applied data science. In the interview, the ZHAW researchers tell us what their recently published papers are about and how their findings can help customers and companies.

Lilach and Jürg, your projects both deal with human-machine interactions. Key words are “industry 4.0” and “smart services”. Can you explain these terms and give examples?

Lilach: One of the main ideas behind Industry 4.0 is to be able to exploit machine data for efficient, or “smart” machine operation. Smart services include the digitalisation of operation and maintenance of machines. To give an example: The operation of large machine fleets requires continuous monitoring of the health of these machines, automated fault detection, diagnostics and, if possible, even prognostics. This is sometimes termed as “predictive maintenance” and typically relies on intelligent algorithms.

Jürg: My favourite perspective of Industry 4.0 is connected to this idea. We can leverage digital technology to create value in real world processes. For example, by enabling human beings to achieve their goals better, faster, or more comprehensively. And this brings us precisely to the term “smart services”: mutual value creation among human beings by the application of data and digital technology!

You both want to improve different processes. Can you sum up the similarities and differences of each other’s project?

Lilach and Jürg: First of all, we would both like to express our grateful thanks to our co-authors who contributed significantly to the work (list of co-authors see in the references at the end of the blog).

Jürg: The two papers are actually complementary, as they both focus on smart services, though from different perspectives. The paper of Lilach and her co-authors investigates how intelligent algorithms can be improved technically to be scalable and relevant for commercial fleets of complex machines. To do so, they developed algorithms for a real operational system (wind farms) with methods like machine learning and deep learning.

Lilach: On the other side of the value chain, the research of Jürg and his co-authors focuses on translating the outcomes of algorithms into real business value for a company. They analyse which combinations of smart services create most economic value for both the providers and customers.

What were the main insights and findings?

Jürg: Our model for optimal value creation shows that it is not easy to predict which service configuration is optimal. It takes on the “service paradox”. In theory, the introduction of smart services in a product-service system should enable companies to improve their business. In practice however, often the opposite happens: companies lose money and economic value is destroyed. The new quantitative methodology that was developed in my DIZH fellowship is thus useful in practice for industrial companies and further advances the research in the field of service value creation.

Lilach: Our paper sheds light on some of the important aspects of deep learning algorithms for predictive maintenance that allow them to be used in real commercial systems. We address questions like how to automate the entire data pipeline, how to deal with the heterogeneity of large fleets of complex machines and with issues of data scarcity. These aspects are rarely addressed in the scientific literature because most of the research is developed with synthetic data. However, at the ZHAW we work almost exclusively with real operational data of our project partners. This confronts us with a completely new set of challenges compared to the academic community and enables us to bridge the gap between research and industry.

Let us look into the future: which projects are next?

Jürg: There are plenty of opportunities for future work. A very interesting direction we follow, for instance, is tailoring our model to specific company situations and finding typical, promising service patterns for specific company types. Another direction is the integration of and extension to ecological value. Smart services have a high potential to reduce the ecological impact in industry if they are designed adequately. We are just about to publish a new paper concerning this topic.

Lilach: In the smart maintenance team we are pretty much flooded with project requests of companies from very diverse application fields. Each one has its own requirements, posing different challenges on algorithm development and scaled implementation. We notice more and more that together with the advances of data science we should not forget the vast amount of domain knowledge lying around at these companies. Therefore, we are driven towards hybrid techniques that combine machine learning with physical models and/or engineering knowledge. Luckily, all our 3 senior researchers are either physicists or engineers, so the combination of data and physics is very natural to us. We truly believe that this is the most promising direction for future research.

Sources and more information:

- Ulmer, M., Zgraggen, J., Pizza, G., & Huber, L. G. (2022). Scaling Up Deep Learning Based Predictive Maintenance for Commercial Machine Fleets: A Case Study. 2022 9th Swiss Conference on Data Science (SDS), 40–46. https://doi.org/10.1109/SDS54800.2022.00014

- Meierhofer, J., Benedech, R., & Heitz, C. (2022). On the Value of Data: Multi-Objective Maximization of Value Creation in Data-Driven Industrial Services. 2022 9th Swiss Conference on Data Science (SDS), 33–39. https://doi.org/10.1109/SDS54800.2022.00013

- Videos & Slides – SDS2022